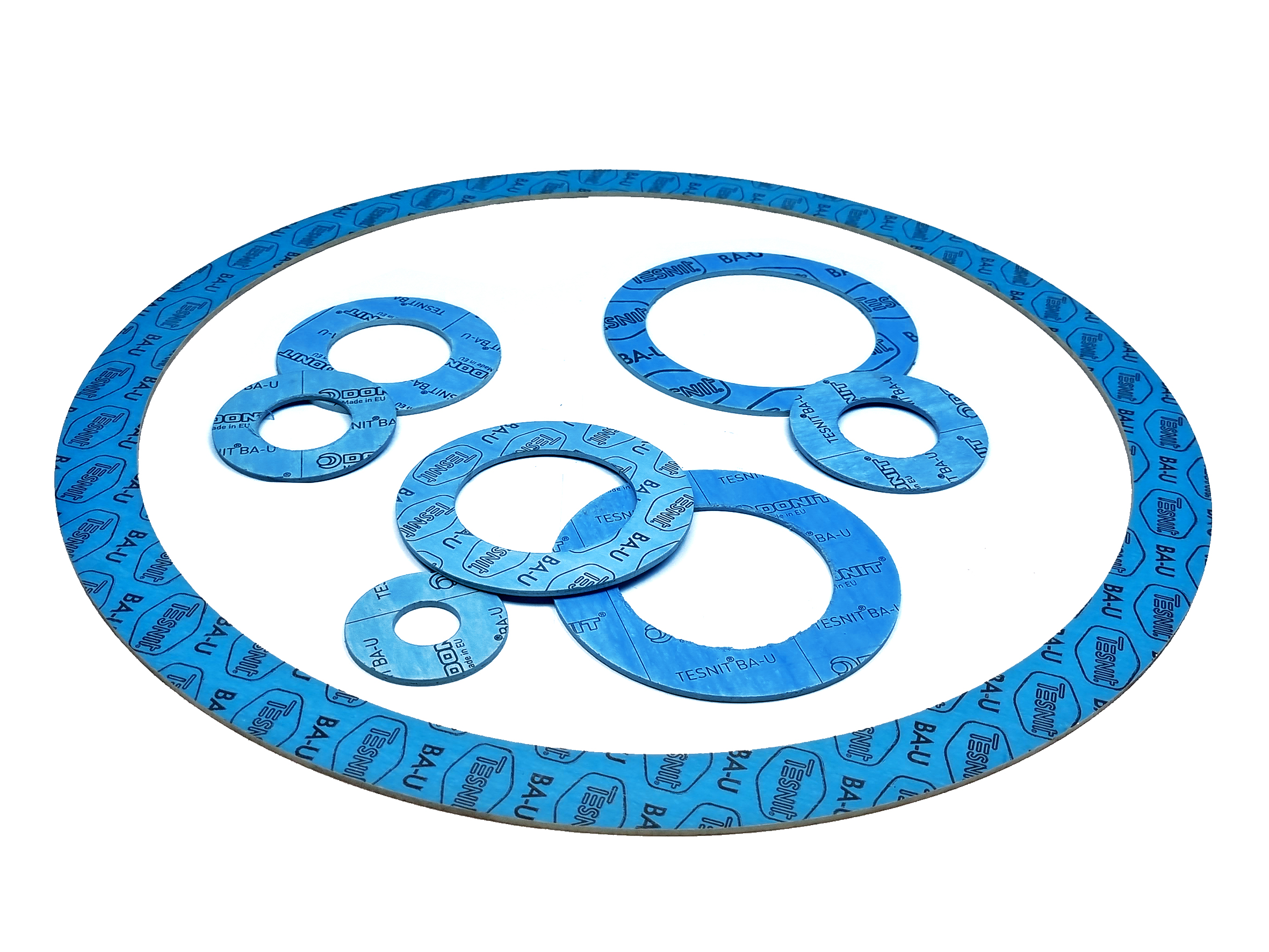

Flange gaskets

Flange gaskets are used to seal flanged connections.

These seals are made of asbestos-free Klingerite.

Standard thickness: 3mm (other thicknesses on request).

Standard dimensions : ½’’ to 8’’

| Part number | Dimension (mm) | Ø of the flange |

| JSA15 | 51 x 27 x 3 | ½ ‘’ |

| JSA20 | 62 x 26 x 3 | ¾’’ |

| JSA25 | 71 x 34 x 3 | 1’’ |

| JSA32 | 82 x 42 x 3 | 1’’1/4 |

| JSA40 | 92 x 47 x 3 | 1’’1/2 |

| JSA50 | 109 x 61 x 3 | 2’’ |

| JSA65 | 127 x 77 x 3 | 2’’1/2 |

| JSA80 | 142 x 90 x 3 | 3’’ |

| JSA100 | 162 x 120 x 3 | 4’’ |

| JSA150 | 224 x 169 x 3 | 6’’ |

| JSA200 | 270 x 200 x 3 | 8’’ |

Product categories

This product is present in the following categories:

- Industrial gases > Ammoniac - NH3 > Equipment for tanks and pipings > Couplings and flanges

- Industrial gases > Refrigerant gases > Equipment for tanks and pipings > Couplings and flanges

- LPG > LPG storage > Under ground big bulk LPG storage tanks > Drain

- LPG > LPG storage > Small bulk LPG storage tanks > Drain

- LPG > LPG storage > Above ground big bulk LPG storage tanks > Drain

- LPG > LPG storage > Above ground big bulk LPG storage tanks > Filling

- LPG > LPG storage > Under ground big bulk LPG storage tanks > Filling

- LPG > LPG storage > Pipings and accessories > Flanges and accessories

- LPG > LPG storage > Above ground big bulk LPG storage tanks > Liquid withdrawal

- LPG > LPG storage > Under ground big bulk LPG storage tanks > Liquid withdrawal

- LPG > LPG transport and distribution > LPG Tank cars > Vapor and liquid phase

- LPG > LPG storage > Under ground big bulk LPG storage tanks > Vapor phase

- LPG > LPG storage > Above ground big bulk LPG storage tanks > Vapor phase